Unfortunately, there is a distinct lack of imagery of the interior workings of a mortice lock, so I hope you don't mind if I use my own images to explain it. Now yet again, there are several types of mortice lock, so i will be making the standard 5 lever lock that would be found in most homes. This means that you will require no external parts to make this, everything you need will come from the printer. There are a huge number of different types of locks out there, but I decided to demonstrate the mortice lock as it is one of the few locks that can be made without using any springs. Ok, now that the boring part is over, let's take a look at what we're going to be making! Allow a small gap (~0.5mm, depending on the quality of the printer) around the edges to ensure the piece will fit smoothly. Trying to insert an object into an exact sized hole will be nearly impossible and require filing/sanding in order to fit. While 3D printing is highly accurate, there is a small amount of bleed in the plastics as they cool, and the ridges of the layers will provide grip to the sides. When making objects to fit inside another, don't make them flush. While it takes up more space on the printer bed to lie everything flat, it will reduce the number of layers and thereby the roughness of the object. Try to limit curves to being printed horizontally. While flat surfaces shouldn't have a problem printing vertically, it can become an issue when printing curves. This means that any vertical detail will have layered ridges, much like a stack of paper (though often rougher as the layers will be thicker than a single sheet of paper on most machines). Thermal extrusion builds up in layers, whose thickness depends on the quality and speed of the printer. Individual STLs of objects also makes it easier to detect and replace faulty pieces.ģ. One of the main problems here is that any models touching against each other will have a layer of support built between them, regardless of whether or not there is space in the 3D file for it, which can cause parts of your model to be lost. As tempting as it is to just export everything together and rush through the printing setup it can easily cause problems, as well as leaving no room for manoeuvring objects in the print setup. Don't try to send multiple objects in one STL file. Most 3D programs have the ability to do this.Ģ. If in doubt of any problems on your model then run an STL check before exporting. If using booleans, try to compile all objects to be cut into one object before cutting. Multiple boolean operations to one object can cause unexpected results. Booleans are a great tool for combing/subtracting objects, but be careful with these. While it can be time consuming to find ways to connect geometry together, especially if detailed, it is necessary. However, if your model has any intersecting details it will have difficulty understanding what is meant to be an exterior or an interior surface, and can easily print the wrong thing. This is basically a 3D placement of the paths of the surfaces on your model. The digital model you send to the printer will be in STL format (Stereo-lithography).

So, for thermal extrusion here is what you need to keep in mind.ġ. Another important aspect of the printer to keep in mind is the type of material you will be printing in, as it will limit the thickness and minimum level of detail it can print.

For the purposes of this instructable I am going to assume the model is being printed using Thermal Extrusion as it is by far the most common form of 3D printing. As a result, the supports need to be cleared away before the part is ready, so interior or interlinking details are not really viable. However, Thermal Extrusion printers heat plastic and print each layer on top of the previous, meaning that it has to create supports to reach any undercuts in the model. For example, a printer using photopolymerization uses light to harden a liquid resin in layers, so when completed the model is simply pulled from the liquid, allowing for all types of undercuts/ interlinking items. There are several types of 3D printer available, and depending on what one you're using will affect the way you make your model.

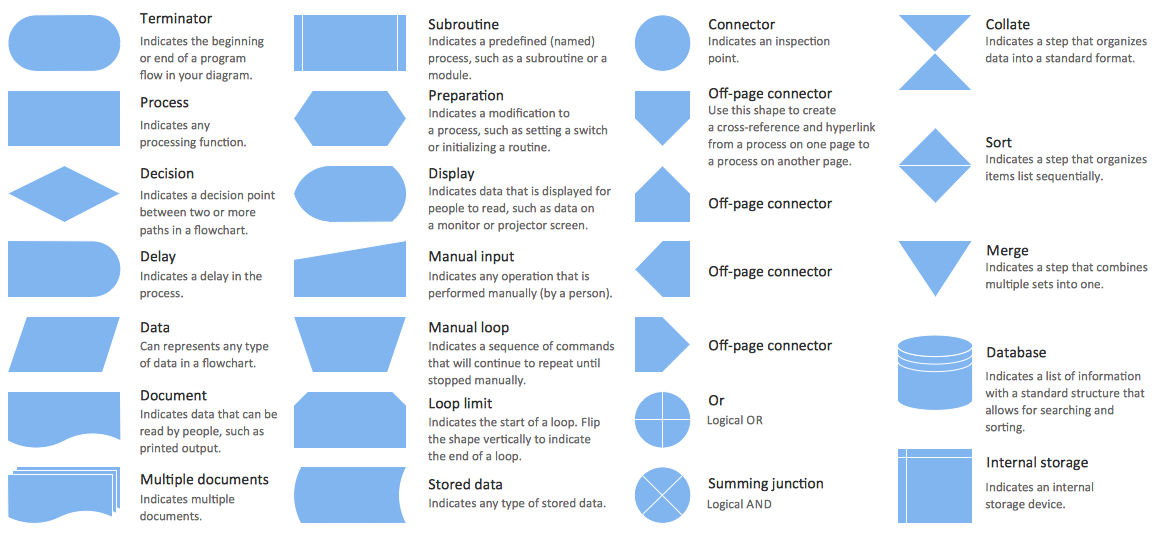

KEYSHAPE MEANING FREE

If you have already used 3D printers, then feel free to skip on to the next page, or take a quick look at the bold writing to double check the basic rules. Firstly, I'm going to run through the basics you need to keep in mind when preparing a model for 3D printing.

0 kommentar(er)

0 kommentar(er)